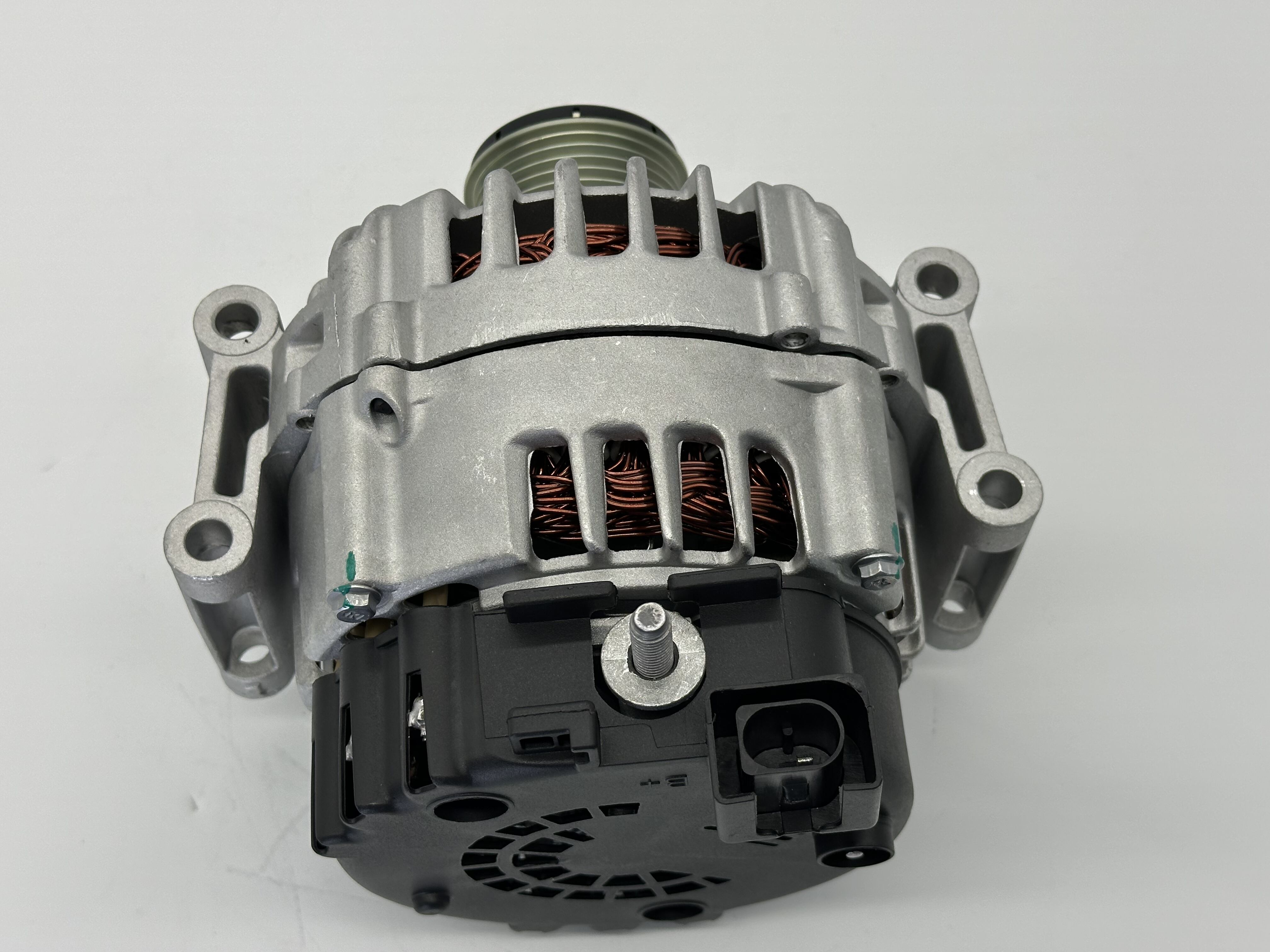

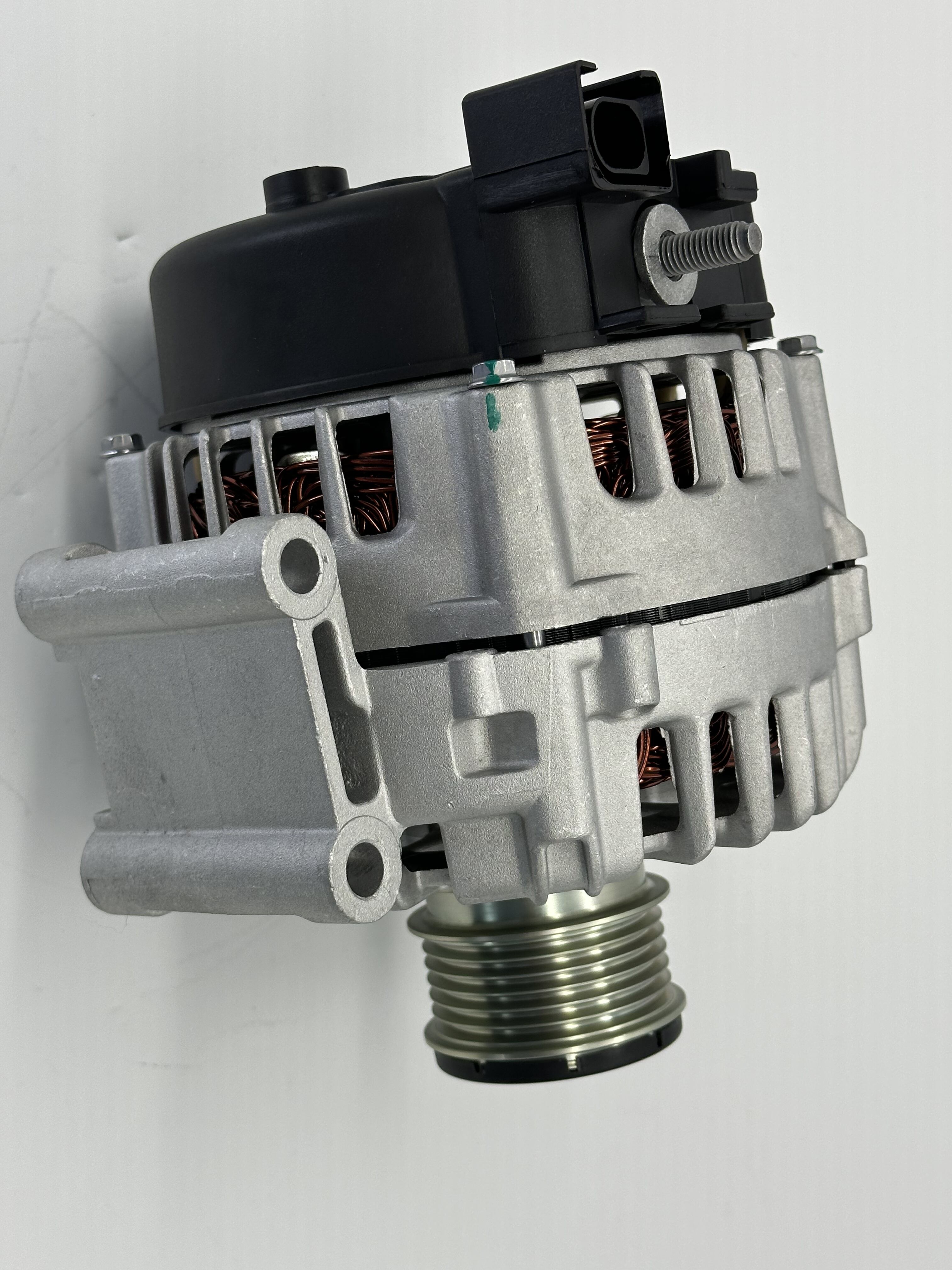

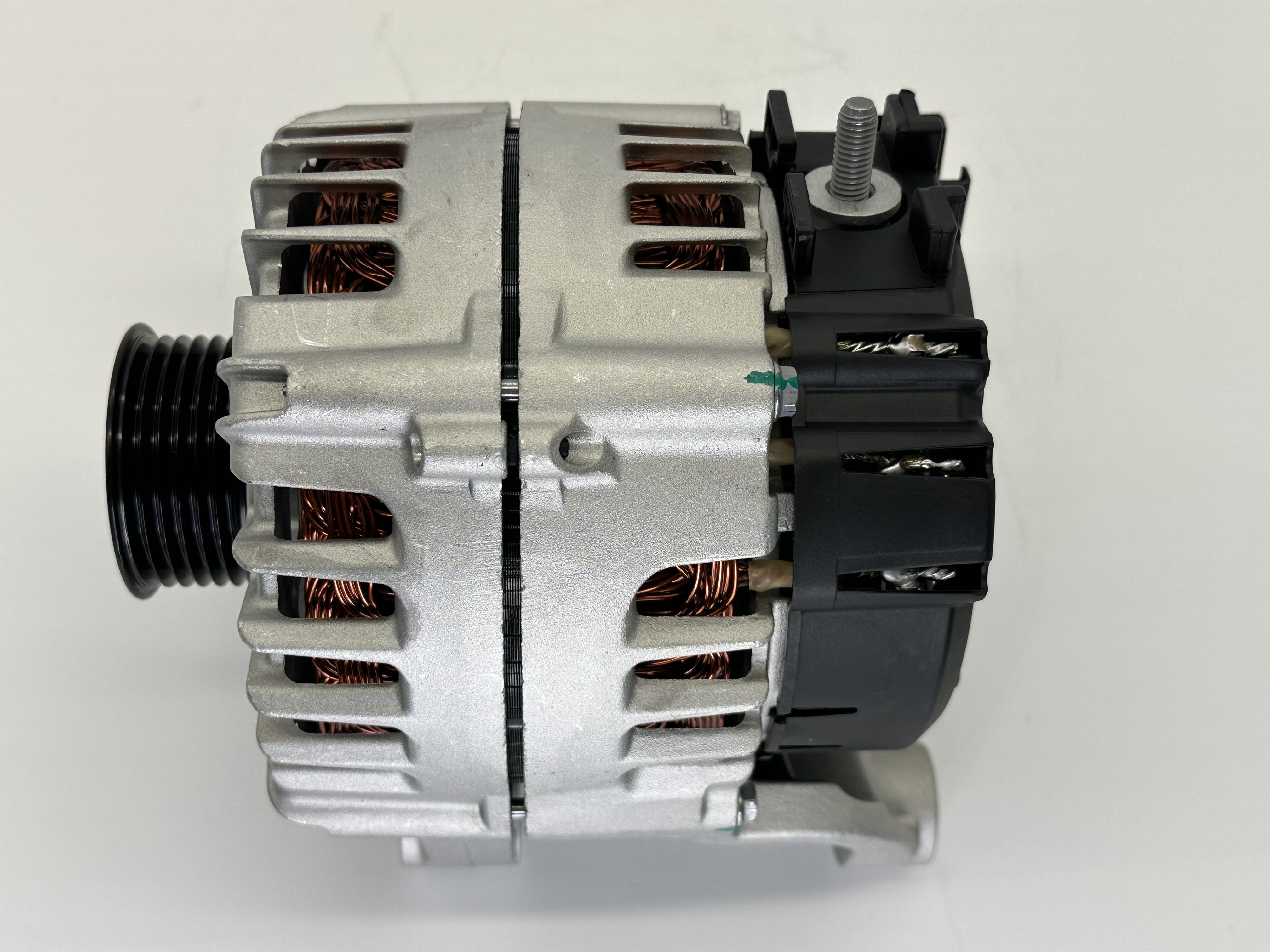

alternator manufacturers

Alternator manufacturers stand at the forefront of power generation technology, specializing in the design and production of essential electrical components that convert mechanical energy into electrical power. These industry leaders employ cutting-edge manufacturing processes and quality control measures to produce reliable alternators for diverse applications. Modern alternator manufacturers integrate advanced features such as smart voltage regulation, enhanced cooling systems, and sophisticated diagnostic capabilities into their products. Their manufacturing facilities utilize state-of-the-art equipment and automated assembly lines to ensure consistent quality and performance. These manufacturers serve various sectors, including automotive, marine, industrial, and backup power generation. They invest heavily in research and development to improve efficiency, reduce environmental impact, and meet evolving industry standards. Quality assurance programs encompass rigorous testing procedures, from component-level inspection to full-load testing of finished products. Many manufacturers also offer customization options to meet specific application requirements, supported by technical expertise and comprehensive after-sales service.