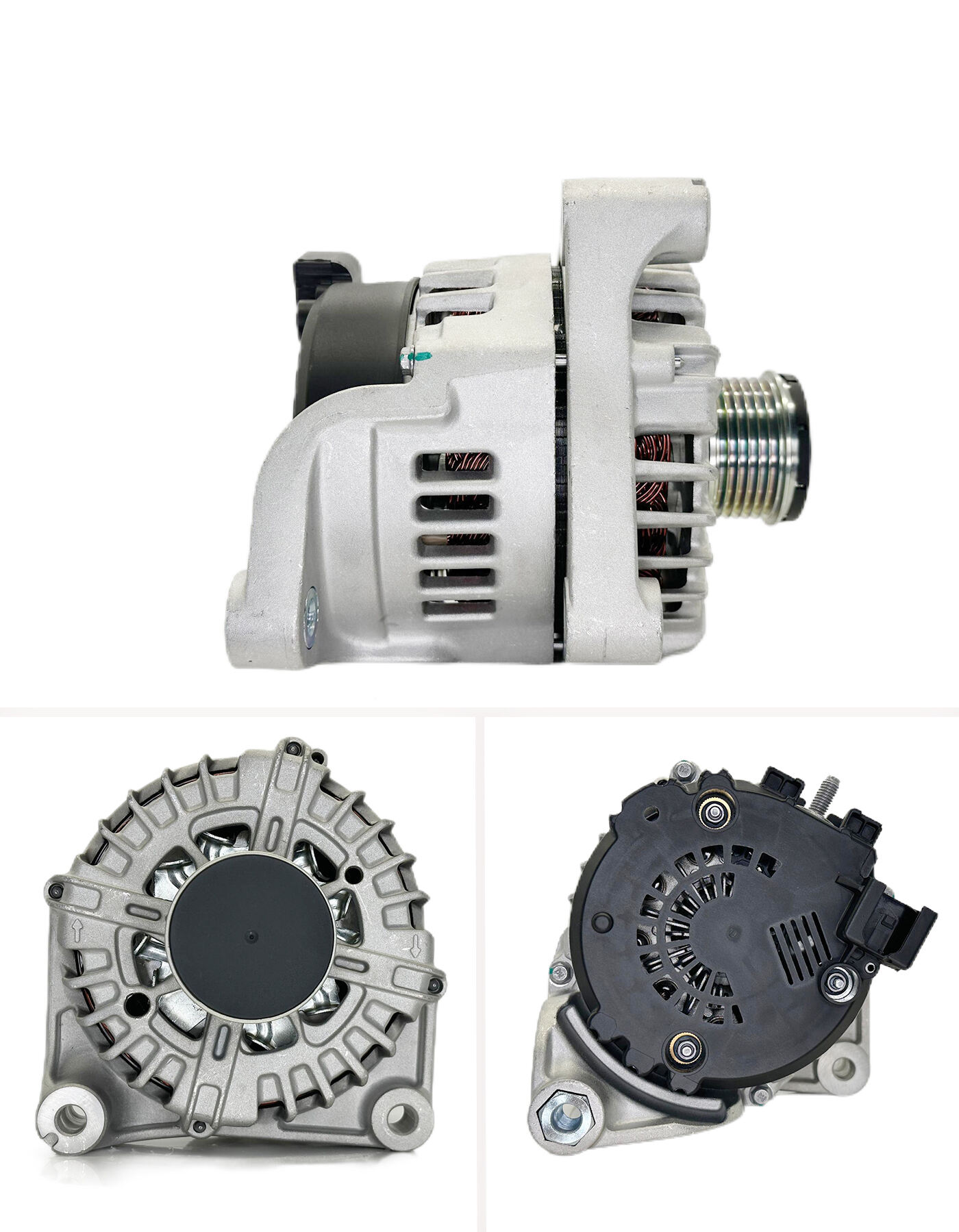

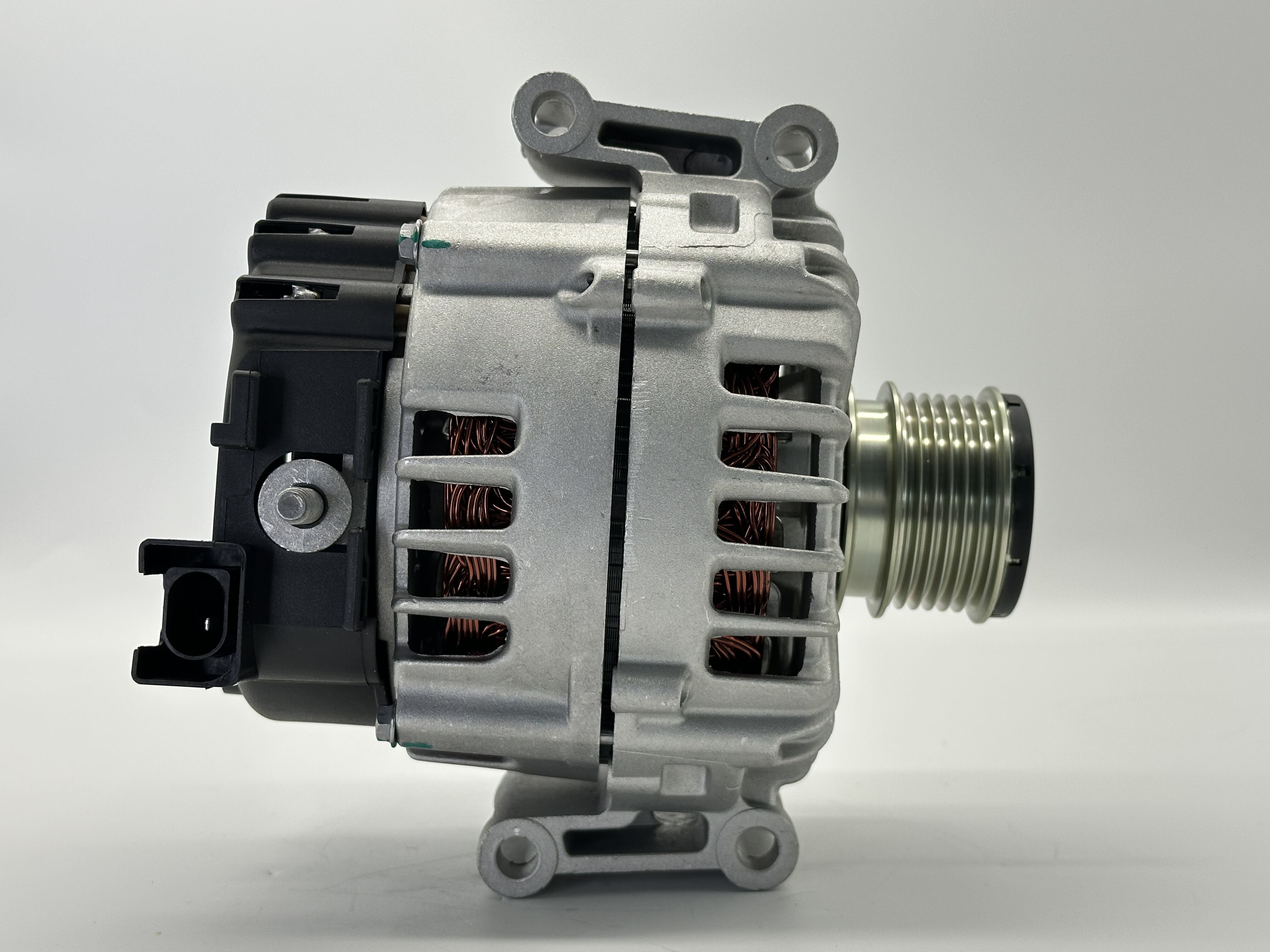

advanced alternator assembly

The advanced alternator assembly represents a significant leap forward in power generation technology, combining innovative design with superior performance capabilities. This sophisticated system integrates cutting-edge electromagnetic components with precision-engineered mechanical elements to deliver consistent and reliable electrical power. At its core, the assembly features a robust rotor-stator configuration enhanced with rare-earth magnets and advanced copper windings, enabling higher energy conversion efficiency than traditional alternatives. The system incorporates smart monitoring capabilities through integrated sensors that continuously track performance metrics, including temperature, voltage output, and rotational speed. These assemblies are specifically designed to meet the demanding requirements of modern vehicles and industrial applications, offering extended operational life and reduced maintenance needs. The unit's compact design maximizes space efficiency while maintaining optimal cooling characteristics through strategically placed ventilation channels. Key applications include automotive systems, marine vessels, industrial power generation, and backup power solutions. The assembly's versatility is further enhanced by its adaptive voltage regulation system, which ensures stable power output across varying operational conditions. This technology proves particularly valuable in applications requiring consistent power delivery under fluctuating load demands.