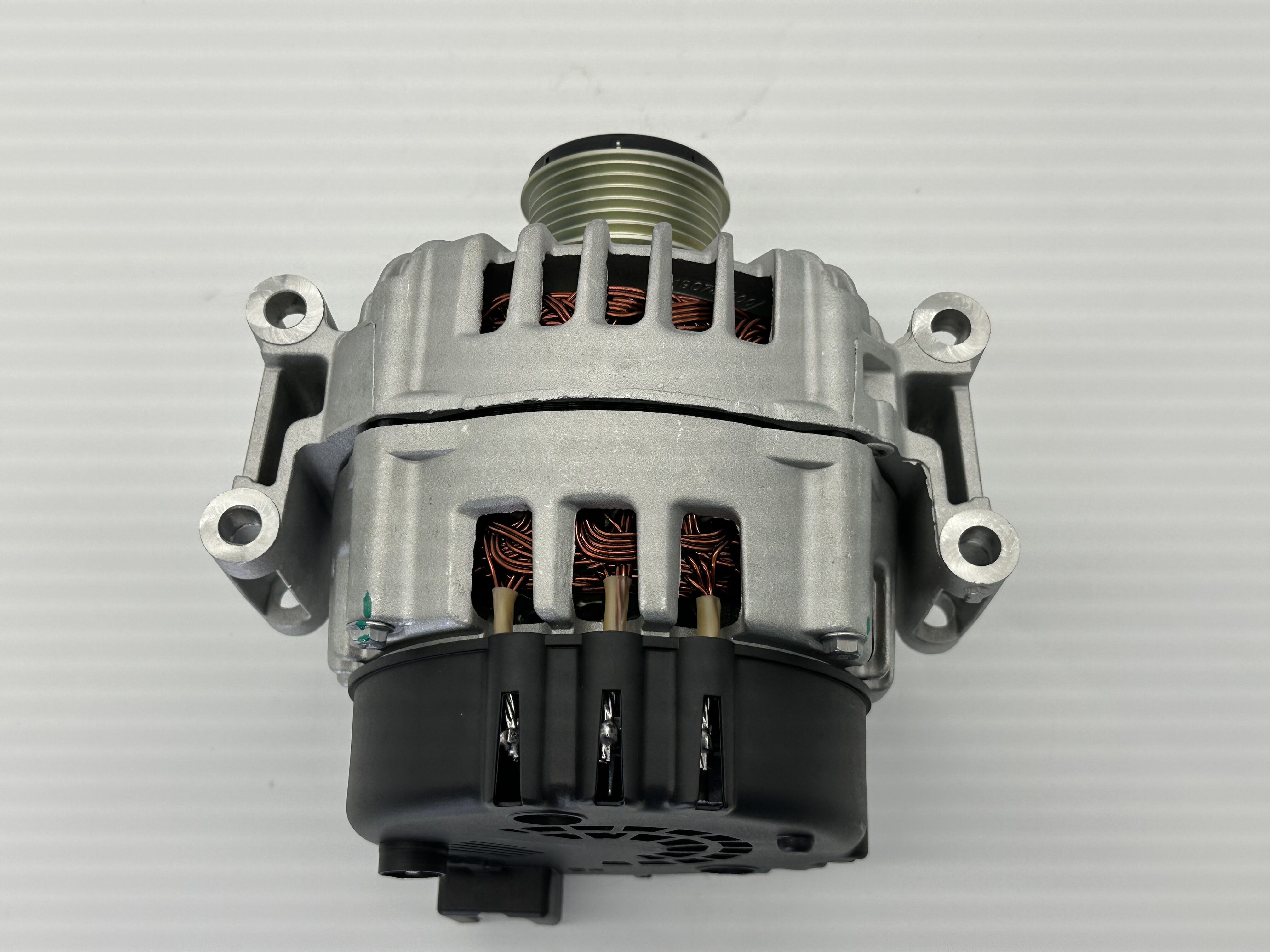

china auto alternator manufacturers

China auto alternator manufacturers have established themselves as global leaders in producing high-quality automotive charging systems. These manufacturers combine advanced technology with cost-effective production methods to create reliable alternators that meet international standards. Their production facilities utilize state-of-the-art equipment and automated assembly lines to ensure consistent quality and precision in manufacturing. These alternators are designed to convert mechanical energy from the engine into electrical energy, effectively charging the vehicle's battery and powering electrical systems. Chinese manufacturers have invested heavily in research and development, resulting in alternators that offer improved efficiency, durability, and performance across various vehicle applications. Their products feature advanced voltage regulators, high-output stators, and robust bearing systems that ensure long-term reliability. These manufacturers also implement strict quality control measures throughout the production process, from raw material selection to final testing. They offer a wide range of alternators suitable for different vehicle types, including passenger cars, commercial vehicles, and heavy-duty equipment. Many of these manufacturers have obtained international certifications such as ISO 9001 and TS 16949, demonstrating their commitment to quality and manufacturing excellence.