Modern vehicles depend heavily on reliable ignition systems to ensure consistent performance and fuel efficiency. The starter motor serves as the critical component that initiates the combustion process by cranking the engine to its optimal starting speed. When automotive enthusiasts and mechanics consider performance upgrades, they often focus on visible modifications while overlooking the fundamental electrical systems that power vehicle operation. Understanding how starter motor functionality directly impacts ignition response can help drivers make informed decisions about their vehicle's electrical infrastructure.

Understanding Starter Motor Mechanics and Performance

Basic Operational Principles

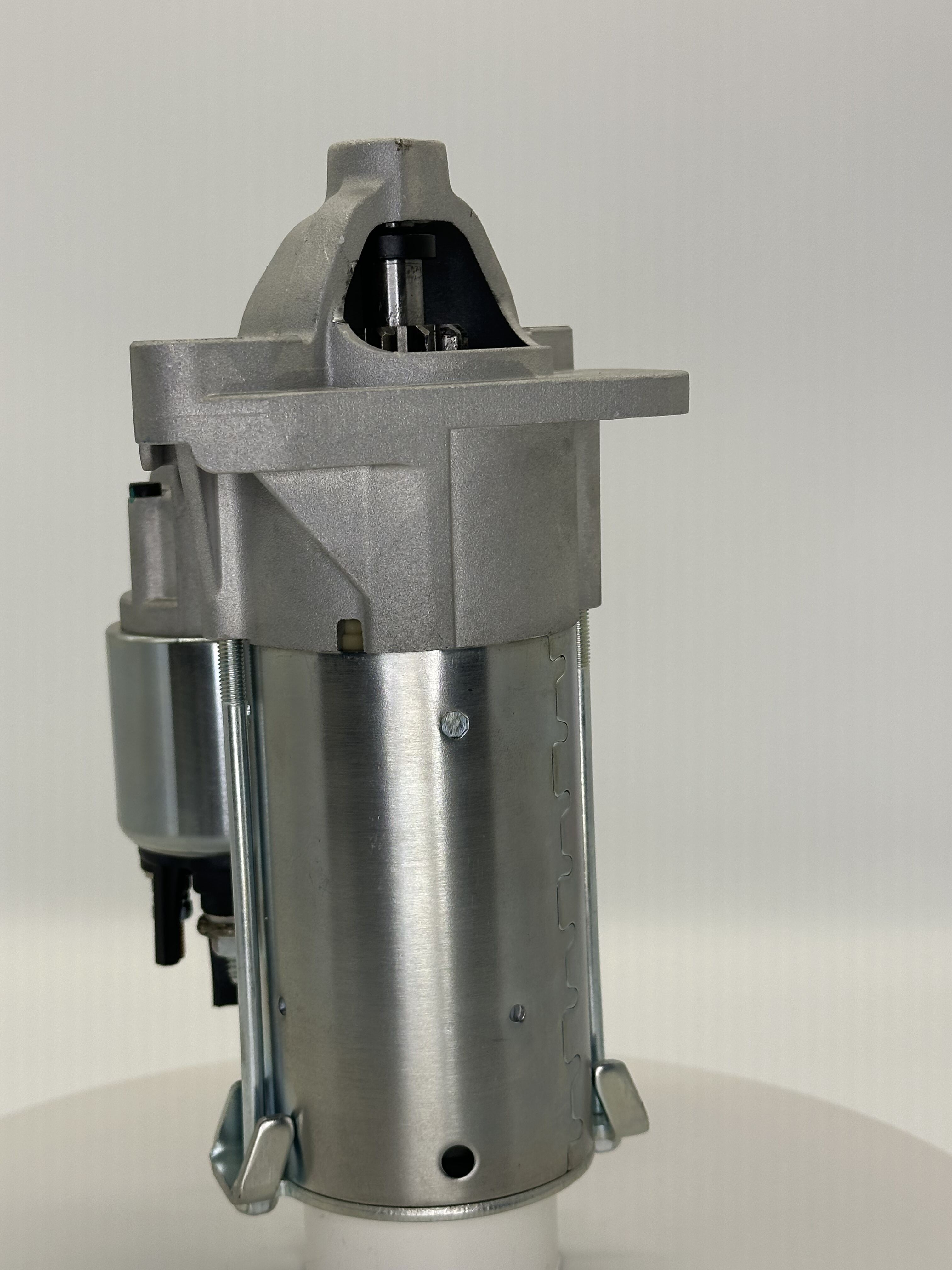

The starter motor operates through electromagnetic induction, converting electrical energy from the vehicle's battery into mechanical rotational force. This process involves a solenoid that engages the starter drive gear with the engine's flywheel ring gear, allowing the motor to rotate the crankshaft at approximately 200-300 RPM. High-quality starter motor assemblies feature precision-engineered armatures, robust field windings, and durable commutator segments that work together to deliver consistent cranking power across various operating conditions.

Advanced starter motor designs incorporate improved bearing systems and enhanced cooling mechanisms to handle extended cranking cycles without overheating. These components directly influence the motor's ability to maintain consistent rotational speed during the ignition sequence. When the starter motor operates efficiently, it provides the engine with adequate compression ratios necessary for proper fuel atomization and spark timing optimization.

Power Delivery and Electrical Efficiency

Electrical efficiency plays a crucial role in starter motor performance, particularly regarding current draw and voltage stability during operation. Premium starter motor units typically feature lower internal resistance, allowing for more efficient power transfer from the battery to the mechanical components. This improved efficiency translates to reduced electrical load on the charging system and more consistent cranking speeds across different ambient temperatures.

Temperature variations significantly affect starter motor performance, with cold weather conditions requiring additional cranking power due to increased oil viscosity and reduced battery capacity. High-performance starter motor assemblies often incorporate specialized materials and coatings that maintain optimal conductivity even under extreme temperature conditions. These enhancements ensure reliable ignition response regardless of environmental factors that might otherwise compromise starting performance.

Impact on Ignition System Response

Cranking Speed and Compression Ratios

Optimal cranking speed directly correlates with engine compression ratios and subsequent ignition timing accuracy. When a starter motor maintains consistent rotational velocity, the engine's pistons achieve proper compression pressures necessary for efficient fuel combustion. Insufficient cranking speed can result in incomplete compression cycles, leading to delayed ignition timing and reduced engine efficiency during startup phases.

Modern fuel injection systems rely heavily on precise timing sequences that coordinate with crankshaft position sensors during the starting process. A high-performance starter motor ensures that these timing sequences remain synchronized, allowing the engine control module to optimize fuel delivery and spark advancement based on real-time cranking conditions. This synchronization becomes particularly important in high-compression engines that require precise timing for reliable ignition.

Electrical System Stability

Voltage stability throughout the starting sequence affects various ignition system components, including spark plugs, ignition coils, and fuel injectors. An efficient starter motor draws consistent current loads, preventing voltage fluctuations that might interfere with sensitive electronic components. When voltage remains stable during cranking, ignition coils can generate stronger spark energy, while fuel injectors maintain accurate spray patterns for optimal air-fuel mixture formation.

Reduced electrical noise from improved starter motor operation also benefits engine management systems that monitor multiple sensor inputs during the starting process. Clean electrical signals enable more accurate readings from crankshaft position sensors, camshaft position sensors, and mass airflow sensors, allowing the engine control module to make precise adjustments to ignition timing and fuel delivery parameters.

Performance Benefits of Starter Motor Upgrades

Enhanced Cold Weather Starting

Upgrading to a high-performance starter motor significantly improves cold weather starting reliability by providing increased torque output at lower temperatures. Cold engine oil creates additional resistance against piston movement, requiring extra cranking power to achieve proper compression ratios. Premium starter motor designs incorporate larger armature assemblies and more powerful field windings that deliver superior torque characteristics even when operating at reduced battery voltages.

Advanced starter motor units also feature improved gear reduction systems that multiply the motor's rotational force while maintaining optimal cranking speeds. This mechanical advantage becomes particularly beneficial when starting engines with higher compression ratios or larger displacement configurations. The enhanced torque delivery ensures consistent ignition response across a wider range of operating conditions, reducing the likelihood of extended cranking periods that might drain the battery or flood the combustion chambers.

Longevity and Reliability Improvements

Quality starter motor assemblies typically incorporate superior materials and manufacturing processes that extend operational lifespan while maintaining consistent performance characteristics. Upgraded bearing systems reduce internal friction and wear, while improved brush assemblies ensure reliable electrical contact throughout the motor's service life. These enhancements translate to more predictable ignition response over extended periods, reducing the likelihood of unexpected starting failures.

Professional-grade starter motor units often feature sealed construction that protects internal components from moisture, dirt, and corrosive elements commonly encountered in automotive environments. This protection ensures that electrical connections remain clean and secure, preventing resistance buildup that might compromise cranking performance. Additionally, improved heat dissipation systems prevent thermal damage during extended cranking cycles, maintaining optimal performance even under demanding operating conditions.

Installation Considerations and Compatibility

Electrical System Integration

Proper integration of an upgraded starter motor requires careful consideration of the vehicle's existing electrical infrastructure, including battery capacity, alternator output, and wiring harness specifications. High-performance starter motor units may draw different current loads compared to original equipment, necessitating verification that the charging system can adequately support increased electrical demands. Professional installation ensures that all electrical connections meet manufacturer specifications and maintain proper circuit protection.

Modern vehicles incorporate sophisticated engine management systems that monitor starter motor operation through various sensors and control modules. When upgrading the starter motor, technicians must ensure compatibility with existing diagnostic systems to prevent fault codes or operational conflicts. This compatibility verification includes confirming that the new motor's electrical characteristics match the engine control module's monitoring parameters.

Mechanical Fitment and Alignment

Physical compatibility extends beyond simple bolt pattern matching to include proper gear engagement geometry and clearance requirements around the motor housing. Different starter motor designs may feature varying overall dimensions or mounting configurations that require verification against the vehicle's engine bay constraints. Proper alignment between the starter drive gear and flywheel ring gear ensures smooth engagement without excessive wear or operational noise.

Professional installation typically involves precise torque specifications for mounting bolts and electrical connections to ensure reliable operation under vibration and thermal cycling conditions. Incorrect installation procedures can result in premature component failure or reduced starting performance, potentially negating the benefits of the upgrade. Quality installation also includes verification of proper solenoid operation and starter drive engagement travel to confirm optimal mechanical interface with the engine's flywheel assembly.

Maintenance and Performance Optimization

Regular Inspection Procedures

Maintaining optimal starter motor performance requires periodic inspection of electrical connections, mounting hardware, and operational characteristics during routine vehicle maintenance intervals. Visual examination of terminal connections can reveal corrosion or looseness that might compromise electrical conductivity and starting performance. Additionally, monitoring cranking speed consistency and current draw patterns helps identify potential issues before they result in complete starter motor failure.

Professional diagnostic equipment can measure starter motor performance parameters including cranking amperage, voltage drop across connections, and rotational speed under load conditions. These measurements provide objective data for evaluating starter motor condition and identifying optimization opportunities within the broader electrical system. Regular testing ensures that the starter motor continues to deliver reliable ignition response throughout its operational lifespan.

Supporting System Optimization

Maximizing the benefits of an upgraded starter motor often involves optimizing related electrical system components including the battery, alternator, and wiring harnesses. High-performance batteries with improved cold cranking amperage ratings provide more consistent voltage delivery during starting sequences, while upgraded alternators ensure adequate charging capacity to maintain battery condition between starting cycles.

Wiring harness upgrades may include larger gauge conductors and improved connection hardware that reduce voltage drop throughout the starting circuit. These enhancements work synergistically with the upgraded starter motor to deliver maximum performance benefits while maintaining long-term reliability. Proper system optimization ensures that all components operate within their intended parameters, maximizing the overall improvement in ignition response and starting reliability.

FAQ

How does a high-performance starter motor affect fuel economy

A high-performance starter motor can indirectly improve fuel economy by ensuring more consistent ignition timing and reducing extended cranking periods that waste fuel. When the engine starts more efficiently with proper compression ratios, the initial combustion cycles operate more effectively, leading to better overall engine performance. However, the direct impact on fuel economy during normal driving conditions is minimal since the starter motor only operates during engine startup sequences.

What are the signs that indicate a starter motor upgrade might be beneficial

Common indicators include slow or inconsistent cranking speeds, clicking sounds during starting attempts, and increased difficulty starting in cold weather conditions. If the current starter motor requires multiple attempts to engage or produces grinding noises during operation, upgrading to a higher-quality unit can significantly improve ignition response. Additionally, vehicles with performance modifications that increase compression ratios may benefit from starter motor upgrades to handle the additional cranking loads.

Can upgrading the starter motor void vehicle warranty coverage

Installing an aftermarket starter motor typically does not void the entire vehicle warranty, but it may affect coverage for related electrical system components if installation issues cause damage. Most manufacturers cannot void warranty coverage for unrelated components under the Magnuson-Moss Warranty Act. However, it's advisable to use OEM-equivalent or higher-quality replacement parts and ensure professional installation to maintain warranty protection for other vehicle systems.

How long should an upgraded starter motor last compared to original equipment

Quality aftermarket starter motor assemblies often exceed original equipment lifespan due to improved materials and manufacturing processes. While standard starter motors typically last 80,000 to 100,000 miles, premium upgrades can provide 150,000 miles or more of reliable service when properly maintained. The actual lifespan depends on operating conditions, maintenance practices, and the quality of supporting electrical system components including the battery and alternator.