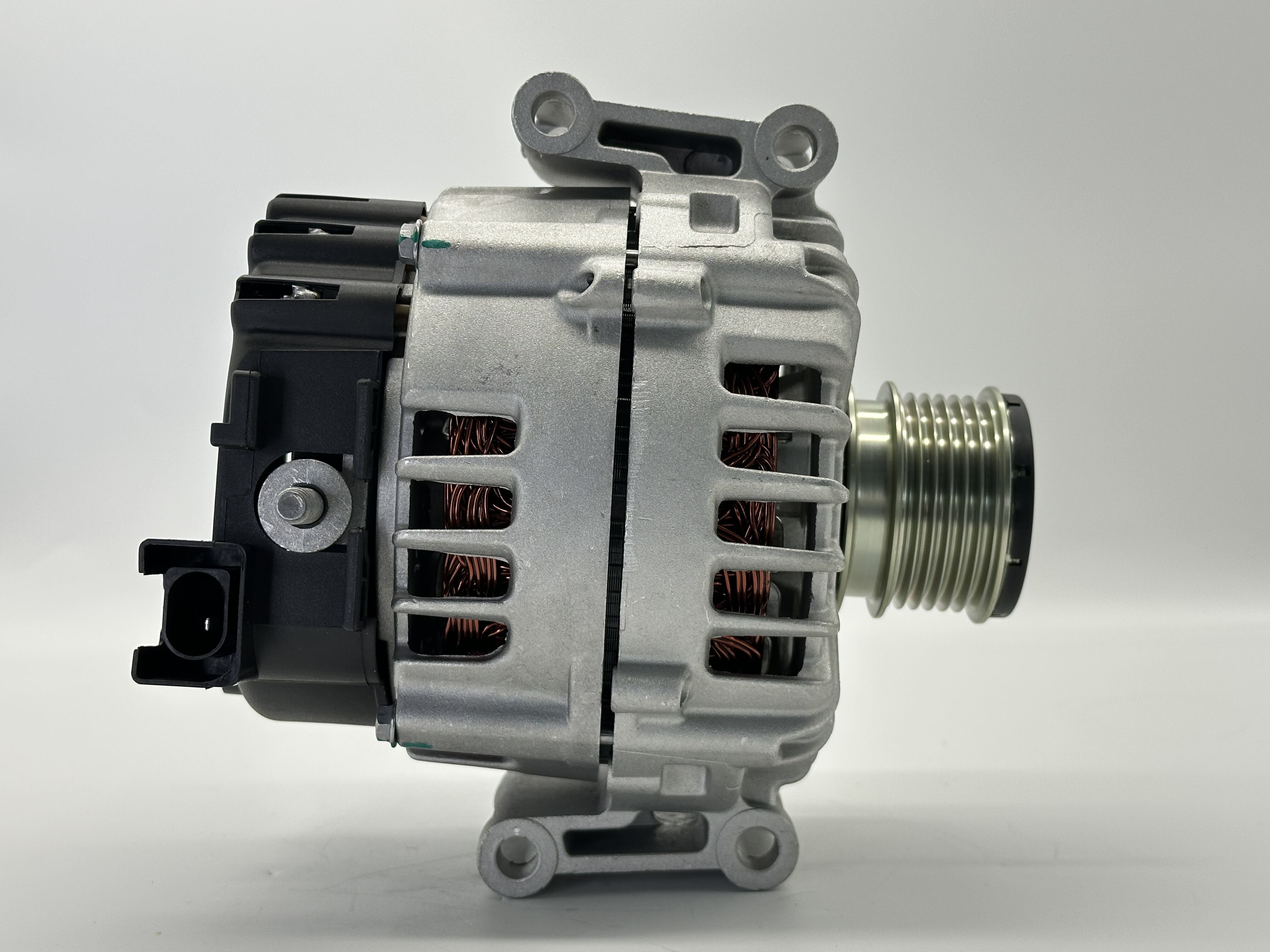

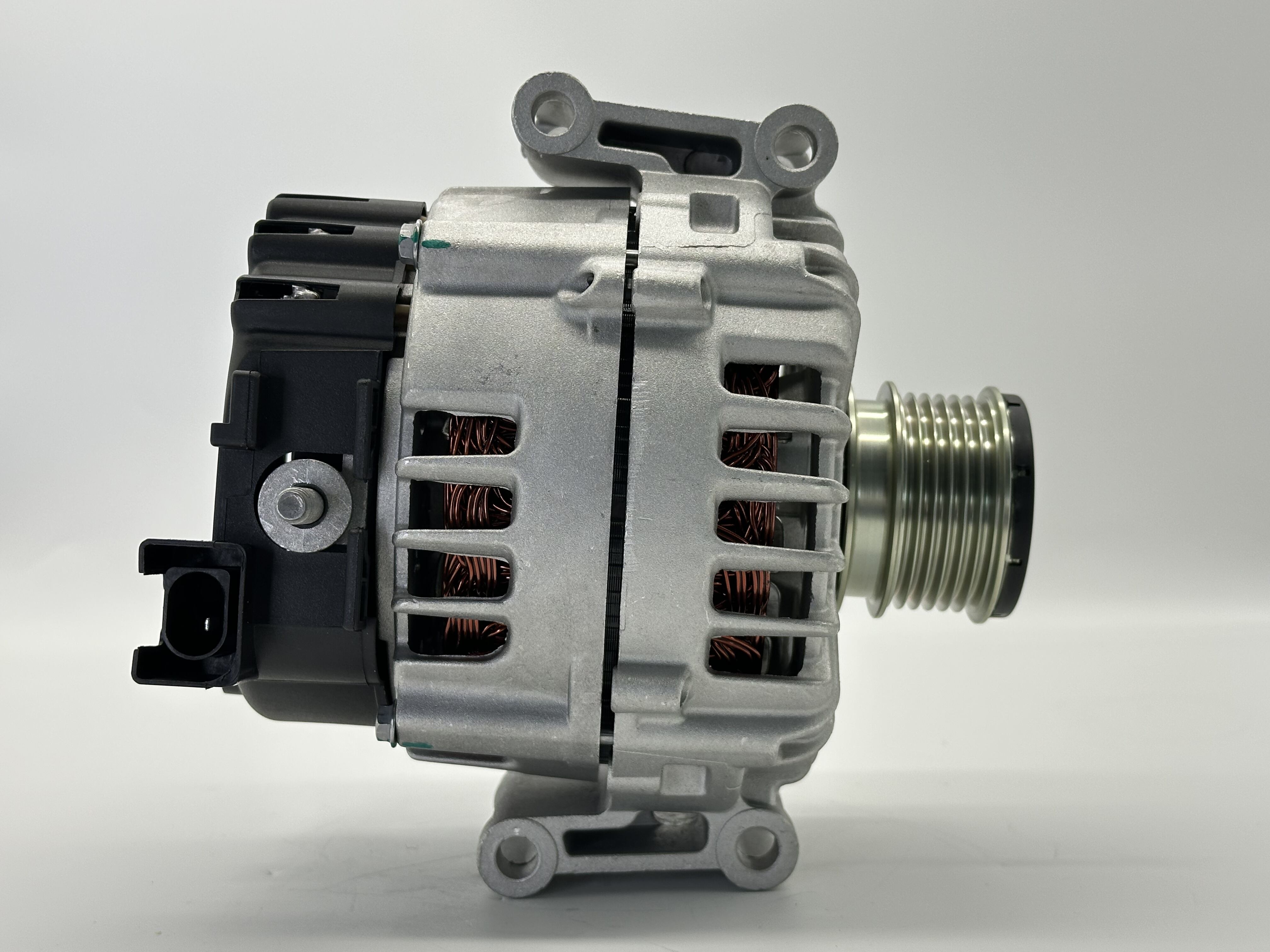

customized alternator

A customized alternator represents a significant advancement in power generation technology, engineered to meet specific requirements and operating conditions. These specialized units are designed to deliver precise voltage outputs while maintaining exceptional efficiency across various applications. The core functionality revolves around converting mechanical energy into electrical power through electromagnetic induction, but with enhanced features tailored to unique specifications. Modern customized alternators incorporate advanced materials and sophisticated control systems, enabling them to maintain stable output under fluctuating load conditions. They feature precision-engineered components, including optimized rotor designs, enhanced cooling systems, and specialized voltage regulators. These units can be configured for various mounting options, drive arrangements, and environmental conditions, making them versatile for different industrial applications. The customization process considers factors such as output requirements, operating environment, duty cycle, and integration requirements with existing systems. Advanced features may include remote monitoring capabilities, automatic voltage regulation, and enhanced protection systems against electrical faults. These alternators are particularly valuable in applications requiring specific voltage outputs, unique physical dimensions, or operation in challenging environmental conditions.