car alternator factory

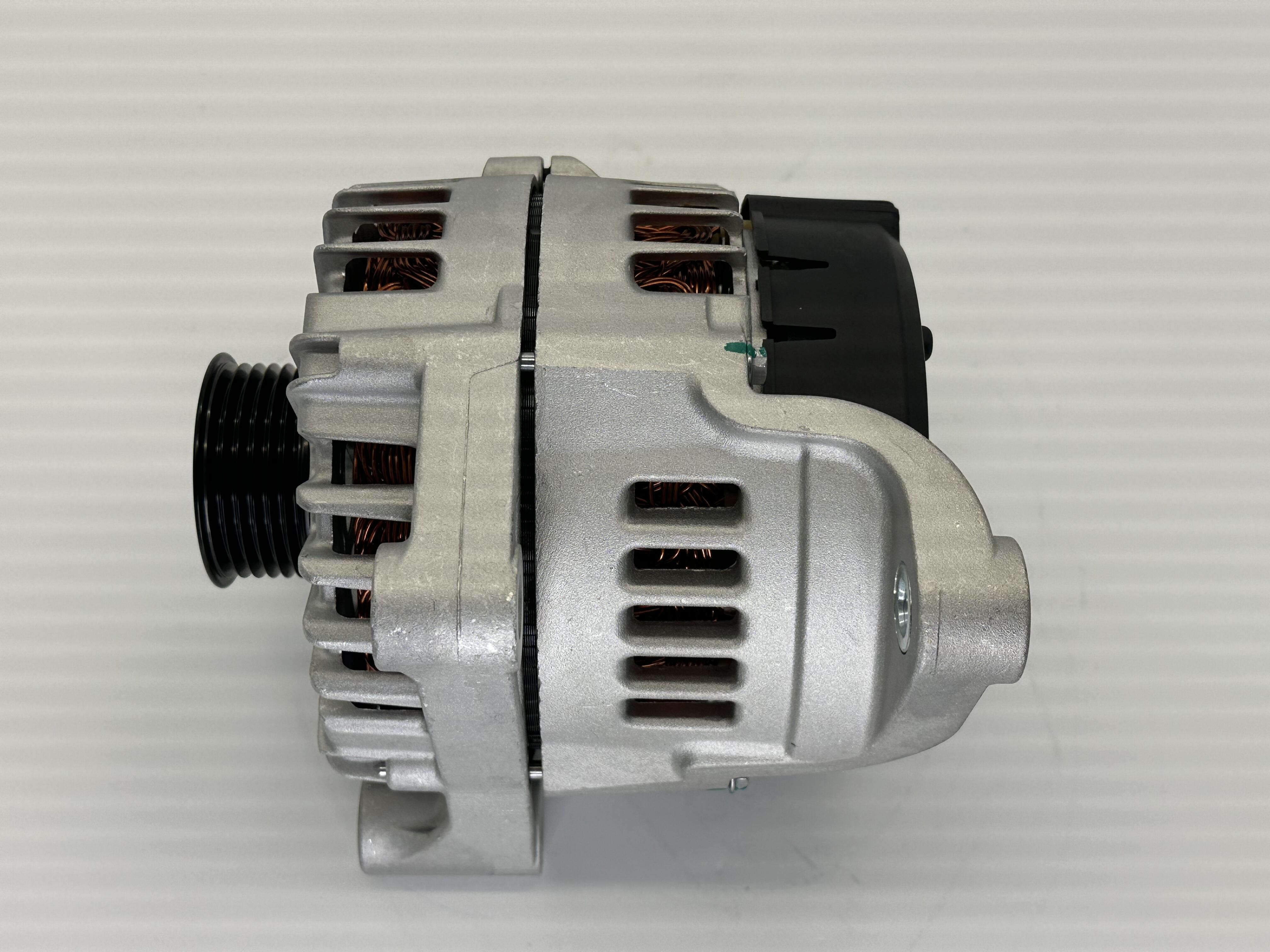

A car alternator factory represents a state-of-the-art manufacturing facility dedicated to producing essential automotive electrical components. These facilities combine advanced automation systems, precision engineering, and quality control measures to manufacture alternators that power vehicle electrical systems. The factory utilizes cutting-edge robotics and assembly lines to ensure consistent production quality, while skilled technicians oversee critical manufacturing phases. Modern alternator factories incorporate testing facilities that simulate real-world conditions, subjecting each unit to rigorous performance and durability checks. The production process includes automated winding of copper coils, precision assembly of rotor and stator components, and integration of voltage regulators and rectifier units. These facilities maintain strict quality control protocols, employing advanced diagnostic equipment to verify alternator output, charging efficiency, and overall performance. The factory's research and development department continuously works on improving alternator designs, focusing on enhanced efficiency, reduced weight, and increased durability. Environmental considerations are also paramount, with many facilities implementing sustainable manufacturing practices and waste reduction programs.