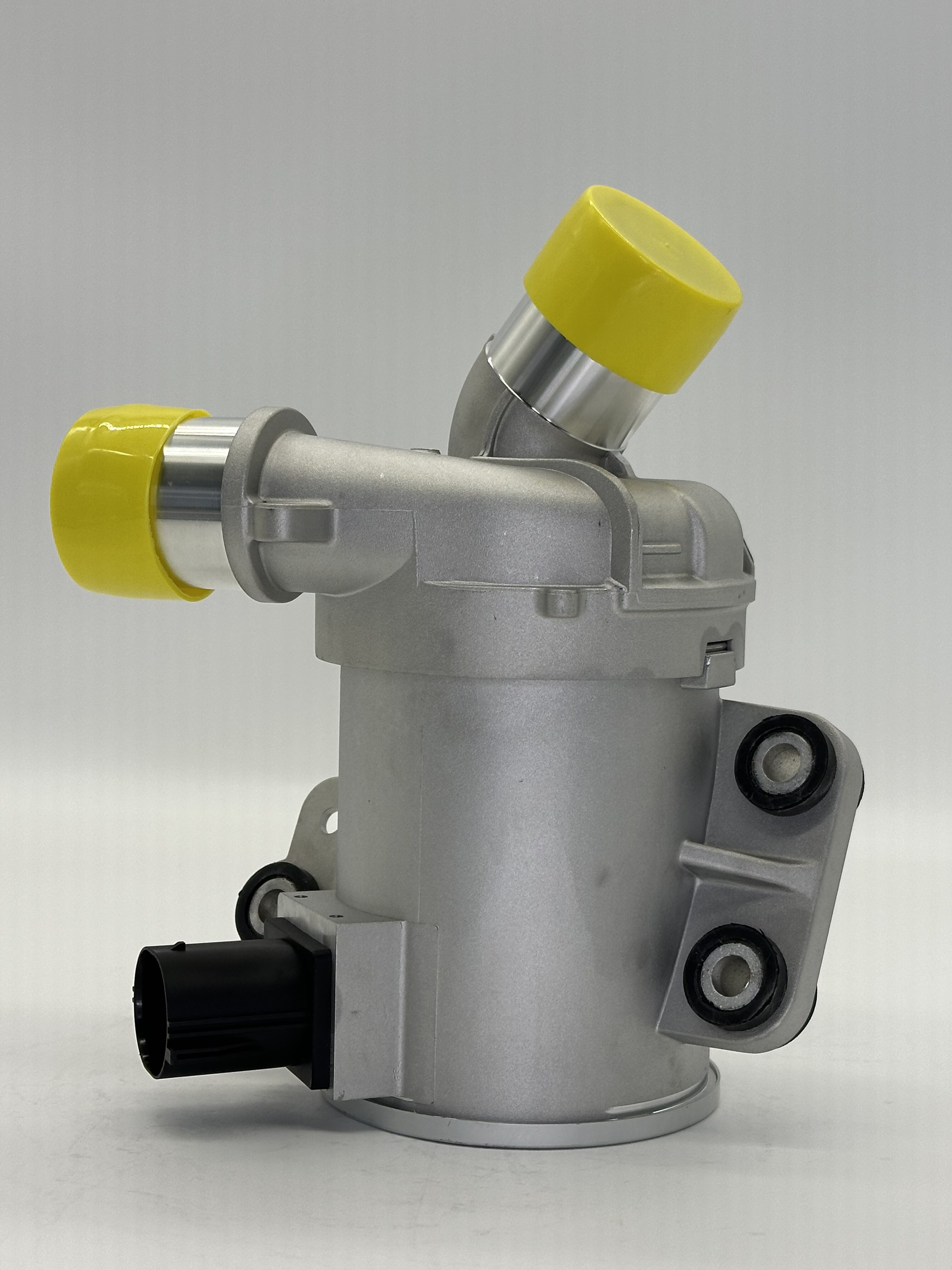

auto water pump factory

An auto water pump factory represents a cutting-edge manufacturing facility dedicated to producing essential automotive cooling system components. The factory incorporates advanced production lines equipped with precision machinery and automated quality control systems, ensuring consistent output of high-quality water pumps. These facilities typically feature state-of-the-art testing equipment, including flow rate analyzers, pressure testing stations, and durability assessment chambers. The manufacturing process encompasses multiple stages, from raw material processing to final assembly, with each step monitored by sophisticated quality management systems. The factory's capabilities extend to producing various water pump models suitable for different vehicle types, from compact cars to heavy-duty trucks. Modern auto water pump factories employ computer-aided design and manufacturing techniques, allowing for rapid prototyping and efficient production scaling. They maintain strict adherence to international automotive standards and often hold certifications like ISO 9001 and TS 16949. The facility's research and development department continuously works on improving pump efficiency, reducing noise levels, and extending product lifespan. Environmental considerations are also paramount, with many factories implementing sustainable manufacturing practices and waste reduction programs.